Week 5: 3D Design, Printing, Scanning

Assignment Overview

This week’s assignment involved designing and printing a small object that could not be easily made by subtractive methods. The tasks included:

- Design and Print a 3D Object

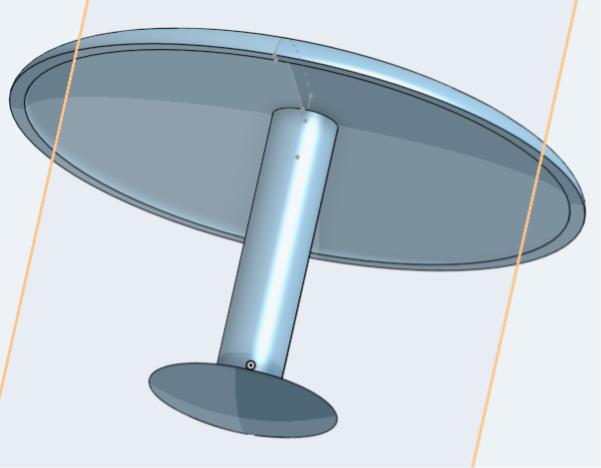

- 3D Model Image:

- STL File: Download my STL file

- Discussion: The object was designed with internal details and features that are not possible to fabricate using subtractive methods. Subtractive manufacturing involves removing material from a solid block, which limits the ability to create complex internal geometries. In contrast, additive manufacturing, such as 3D printing, builds objects layer by layer, allowing for intricate designs with internal structures that cannot be achieved through traditional subtractive techniques. This capability is particularly advantageous for creating lightweight structures, internal channels, and complex assemblies that are integral to the design.

- 3D Model Image:

- Scan an Object

3D Scan:

I recently uploaded a GIF of a scanned mesh using KIRI. The process involved uploading 100 pictures and was quite easy to use. The resulting mesh is of very high quality, making it a valuable tool for 3D modeling and other applications. This experience highlights the efficiency and effectiveness of using KIRI for creating detailed 3D models from simple 2D images. can

- Final Project Update: Clothes Folding Robot

- Schedule:

- Week 1-3: Design and CAD work for the robot.

- Week 4-5: Software integration and expanding features.

- Bill of Materials:

- Stock materials available in the makerspace.

- Additional purchase: Larger servos.

- Schedule:

This documentation provides a comprehensive overview of the tasks completed and the progress on the final project. Further updates will be made as the project develops.