Week 8: CNC Design and Fabrication

Assignment Overview

This week’s assignment involved designing something and making it using CNC technology. The tools available included the ShopBot for 2D outlines, the Shaper for 2D outlines, and the SRM-20 for 2.5D molds. Post-processing options included molding and casting, vacuum forming, or composites.

Design and Fabrication Process

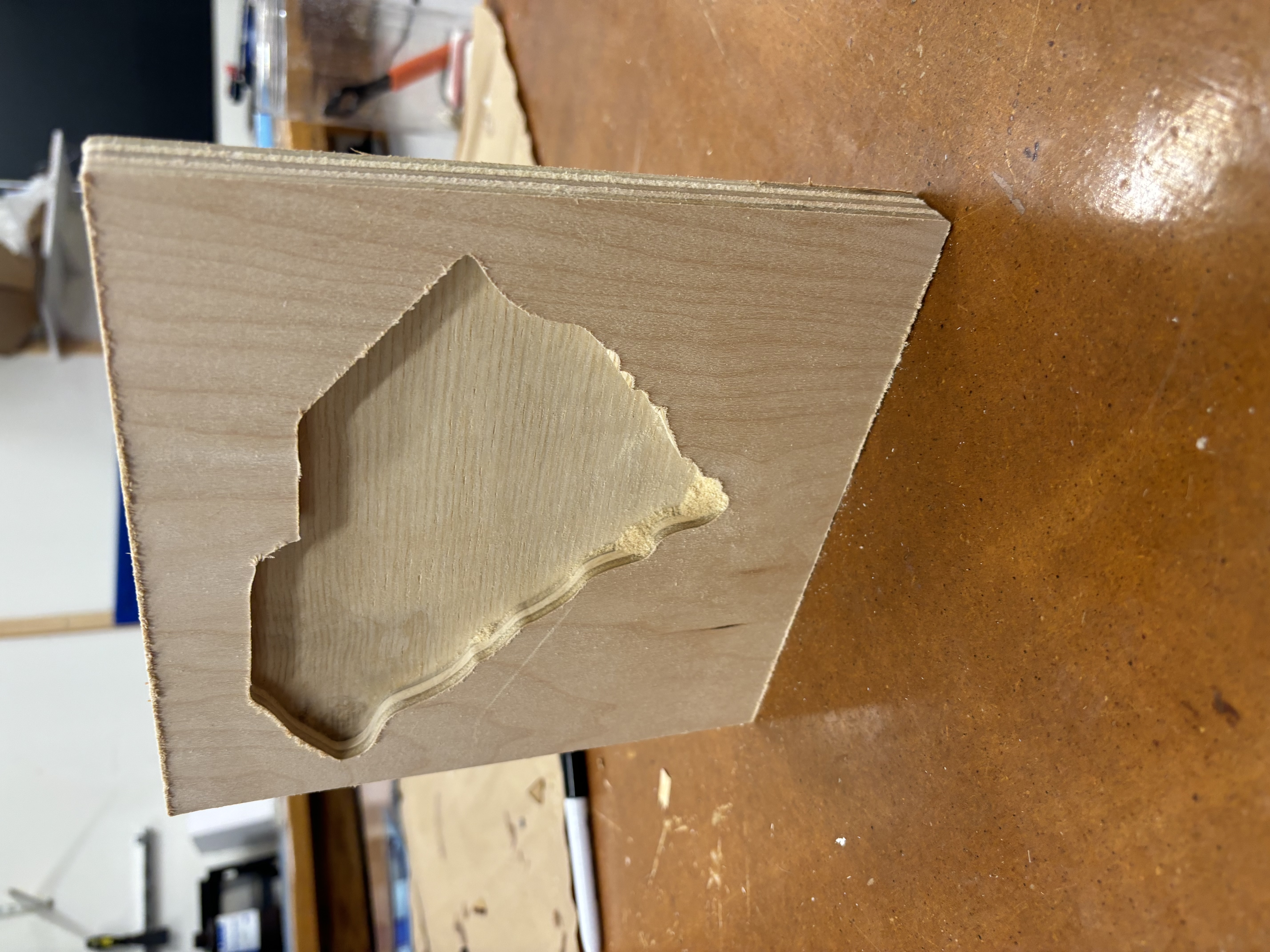

Initial Design Choice: I selected an image that allowed the CNC mill to achieve the appropriate resolution. This decision was crucial in ensuring the precision of the final product. The chosen design was intricate, requiring careful consideration of the CNC tool paths and milling strategies.

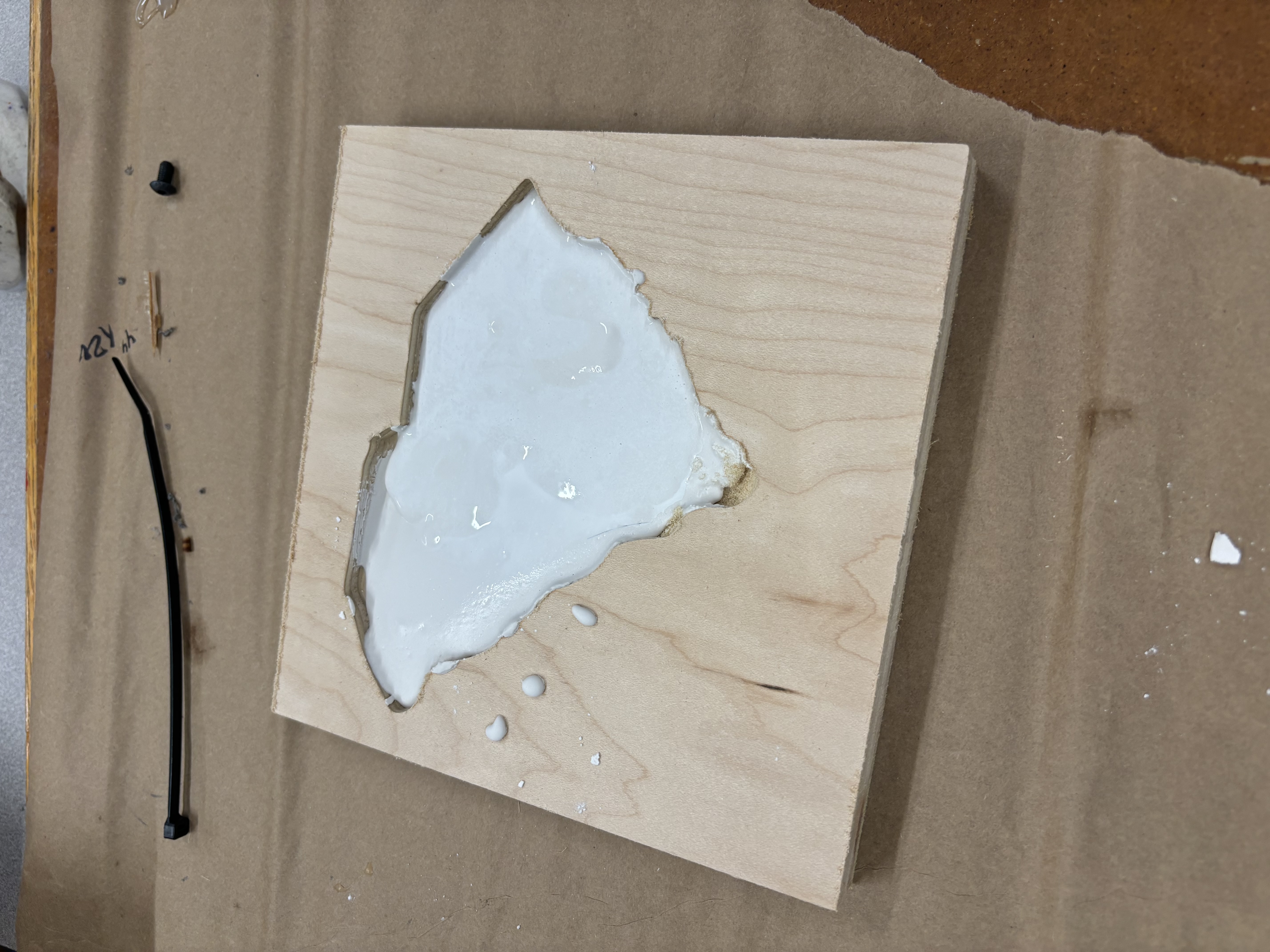

Challenges Faced: One significant challenge was the difficulty in removing the casted item from the negative mold I made of my state, South Carolina. The mold was detailed, capturing the state’s unique contours, which made the demolding process tricky. I attempted various techniques to ease the removal but faced resistance due to the mold’s complex geometry.

Reflection and Future Improvements

Resolution Considerations: Ensuring the selected image is suitable for the CNC mill’s resolution is crucial. In future projects, I will explore different image processing techniques to enhance the design’s compatibility with CNC milling.

Mold Release: In the future, I would explore better mold release techniques to avoid issues with removing casted items. This could involve experimenting with different release agents or incorporating draft angles in the mold design to facilitate easier demolding.

Post-Processing Techniques: Experimenting with different post-processing methods could enhance the final product’s quality. Techniques such as sanding, polishing, or applying surface finishes might improve the aesthetic and functional aspects of the casted item.

Visuals